At HFC, we know that sometimes the idea in your head doesn’t match any of the bone china whiteware that is currently available. To solve this, we offer a ‘bespoke project’ service, in which the whole production process is in your control.

With years of experience in the pottery industry, we have an extensive knowledge on how to help individuals and companies make their designs a reality – from mould making to decorating the finished whiteware. Over the years, we have created a variety of new and unique pieces for several different projects. Please see below for an example of a bespoke project, as well as the step-by-step production process!

The Process

1. Make a hand-built model in plaster from the designers drawings and specification.

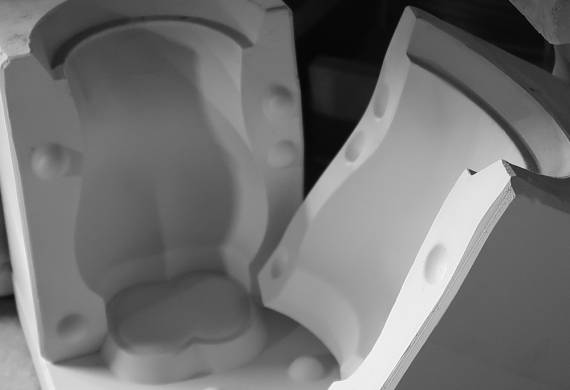

2. Create a block mould from the model.

3. Cast samples in fine china from the block mould to check size/shape. If correct, use the block mould to make a case.

4. Use this case to make large quantities of moulds of consistent quality for an order or production run.

5. Cast , fettle, sponge then fire (1300C) to produce the bisque finish. Brush, glaze and fire (1100C) again to make the white item.

6. Decorate as per the Designers instructions, using hand painted enamel colour or transfers. Fire again in the enamel kiln to around 800C to produce the finished product.

7. Shapes can always be adapted for other uses, such as leaving the handle off and putting a slot in the top – such as a money box!